Contract Manufacturing

Job Work (Fabrication / Contract Manufacturing)

KEO GREEN ENERGY is a leading supplier of precision sheet metal components, assemblies and sheet metal fabrications in the India. Our most valued company asset is our friendly, approachable, hardworking staff which has many years combined experience supplying sheet metal services. This wealth of knowledge and experience enables us to offer an unrivalled, responsive customer service experience. Our experience also enables us to work to the highest standards in every aspect, from design to delivery.

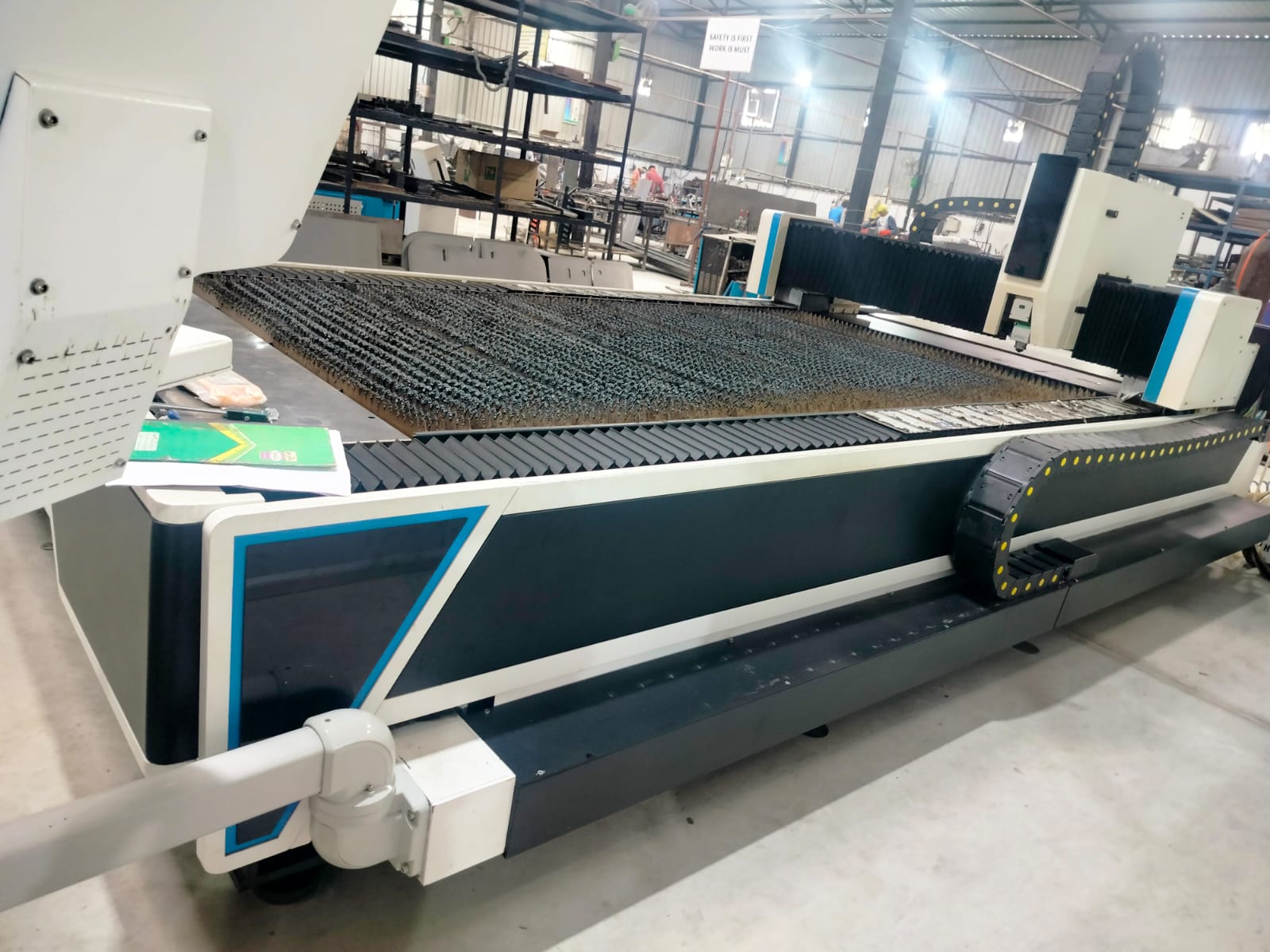

PLANT & MACHINERY

Spread across 1.5 acres in Gurgaon industrial area

The Best In Class Manufacturing Plant. Our plant at Gurugram uses futuristically designed state-of-the-art equipment, managed by one of the most modern Cloud-ERP technology, with a capacity to roll out 10,000 vehicles annually. It has a high level of vertical integration and a large share of local suppliers. The facility is being operated in a green-industrial-belt, supports our philosophy that embodies our goal of creating environment friendly products and solutions.Personal & commercial electric vehicles: KEO GREEN ENERGY have stated their presence in the commercial vehicle market and has emerged as a key player under the segment. Keo Green energy offers – Electric commercial Passenger, transport vehicles & Electric 2 wheeler. The Keo Green energy Auto India ride is for everyone, for every age and for every segment. With key innovations in electric vehicle category Keo Green energy have created benchmark products that provide consumers a viable, convenient and cost effective way to travel.

CAPABILITIES

CREDENTIALS

Leverage our We have in-house State-of-art Manufacturing Facilities in Gurgaon Haryana

- Developed, Made In India power train up to 5KW

- Best Quality Product Compared to the Chinese Counter Parts.

- 100% Genuine and Quality Spare Parts for all E Rickshaw Models.

- Developed, IOT Based Power train

- In-House Research And Development

PLANT & MACHINERY

- 40+ MIG Welding

- 160+ Direct & Indirect staff

- 60+ Fixtures for fabrication parts

- 15+ Heavy duty grinder

- 2 Pipe-cutting machine

- 15+ Heavy-duty drill machine

- 3 Pipe bending machine

- 2 Heavy duty compressor

- Pneumatic assy. line for vehicle manufacturing

- Tire changing / embossing machine

- Powder coating plant – 2 ovens